There are no products listed under this category.

Shop by Category

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

-

Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

-

Bosch, American Bosch, and Robert Bosch

-

American Bosch

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- MRA Magneto American Bosch

- MRF American Bosch Magneto

- DU1,DU2,DU4..Ad nauseum Bosch Catalog 50

- Flywheel Magnetos by American Bosch

- Impulse Coupler RX

- Instruction Book & Agents 1925 Am Bosch

- Service Manual American Bosch Magneto 1928

- ZR4 For Ingersoll Rand Compressor

- ZR4 ZR6 Instruction Manual

- AB 33 and some mumblings on the AB34

- Application Information

- AT4 AT6 Bosch Magneto Instruction Parts Manual

- B4 + B6 Manual

- Bosch Magneto Service Parts List 1922

- DU Service Manual

- FX1 American Bosch Magneto Parts List

- Home of the Bosch Magneto

- MRD Am Bosch Magneto Service Manual

- MVA American Bosch Magneto Instruction Manual

- U1 U2 U4 U6 Debut Whatsa Matter U?

- ZR4 Service manual

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- Bosch

- Robert Bosch

-

American Bosch

-

Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

-

Flywheel Magnetos by Eisemann

- Eisemann 61-D flywheel magneto

- Eisemann 61Cflywheel Mag

- eisemann 61DA Flywheel magneto

- Eisemann 61DC flywheel magneto

- Eisemann 61DE Flywheel magneto

- Eisemann 61DF Flywheel magneto

- Eisemann 61DH Flywheel magneto

- Eisemann 61NA flywheel magneto

- Eisemann 62-D Flywheel magneto

- Eisemann 72C Flywheel Magneto

- Eisemann 72D Maytag Magneto

- Eisemann 72DA Maytag Magneto Service

- Eisemann 82-D and 82-F Flywheel Mags

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

-

Dixie and Aero Magnetos

- Dixie 46 246 462 Magneto Parts List

- Aero 448 449 648 649 Magneto

- Aero AE Magneto Manual

- Aero Magneto Catalog 1925

- Dixie 235 Oscillating Magneto

- Dixie 40 42 and 44 Magneto Manual N-404A 1919

- Dixie 46 Magneto Manual N-403C 1919

- Dixie 8 Cylinder Magnetos #83-86

- Dixie Aero Service Info

- Dixie Magneto Model 60 and 63 Catalog 1915

- Dixie Splitdorf Magneto Catalog N-401

- Splitdorf 46T and EM Impulse Starter

- Splitdorf Dixie M1 & M2 Magneto

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

- Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

- Bosch, American Bosch, and Robert Bosch

- Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

- Flywheel Magnetos by Eisemann

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

- Dixie and Aero Magnetos

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

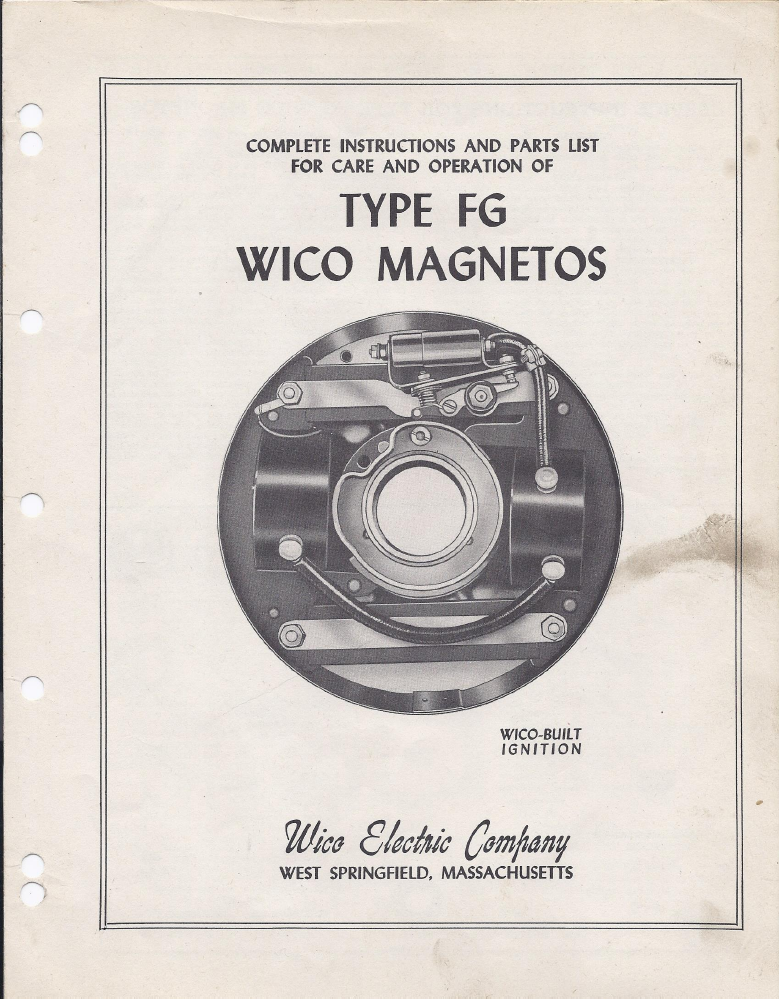

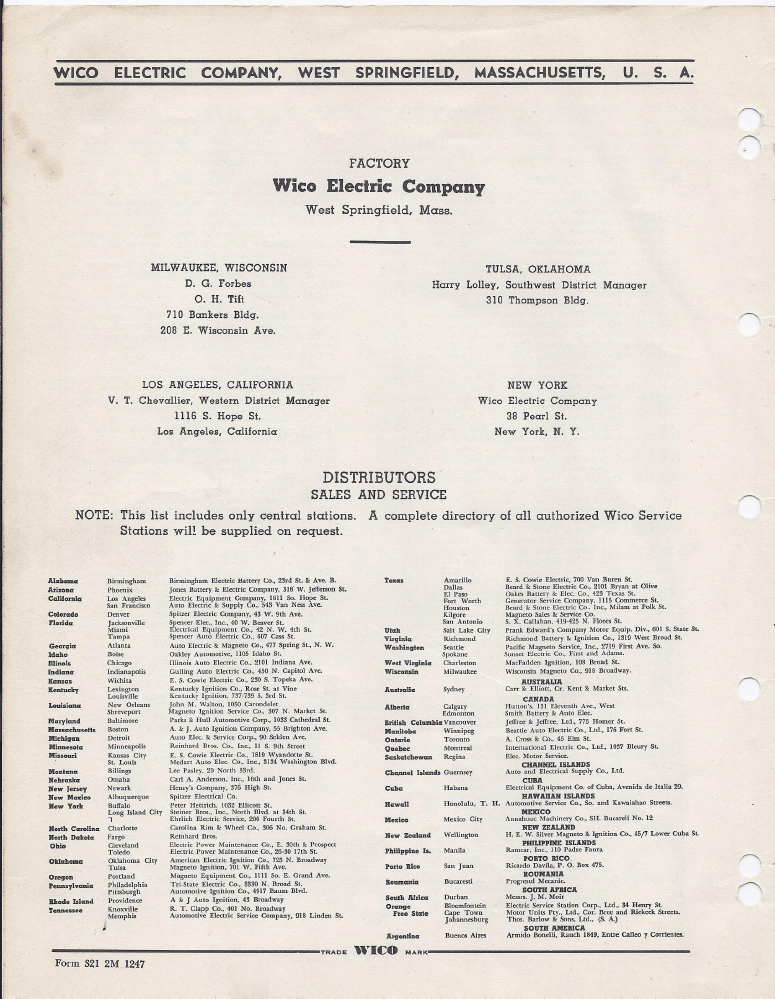

F Series: F,FG,FGM,FGS

Wico F Series: Flywheel and Just Plain Weird

Wico made some magnetos to serve the small air cooled engine market. Not all flywheel magnetos at first, but shared many of the features and annoyances. The early models used two coils wired in series and two magnets, reminiscent of the famous model EK, later they used one coil and one magnet and life became much less complicated. Later designs used one coil and magnet with a three poleshoes. This design was more compact and efficient. Problem areas are the usual ravages of moisture, abuse and neglect. The latest evolution of the F series are the FW actual flywheel magnetos with a design that endures today. Always check the condensers for leakage. Unlike wine, they don't improve with age, especially in the soggy Northwest. Points nearly always need attention, especially with a bad condenser in the circuit. Here is some service information on some of their earlier models to help keep yours alive and well.

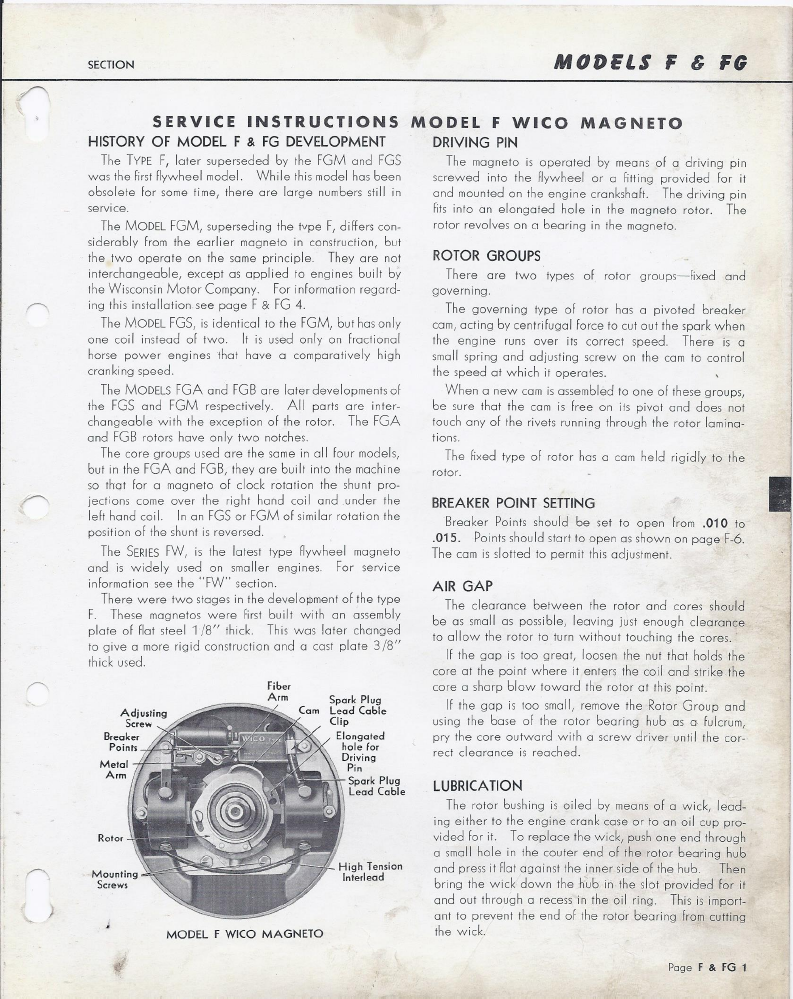

The model F was an early offering using two coils, two magnets and a centrally located rotating core, later replaced by the FG,FGM and FGS. Here are some images from a factory manual describing the F series. Fortunately, the F,FG,FGM and FGS appeared only briefly and were replaced by the much improved FW to be discussed later. If the breaker cam has a small spring behind it this a governor cam. When the rotor reaches a governed speed the cam pivots away from the breaker lever and halts the spark. The FW was used extensively my Maytag on their later twin cylinder models.

Life gets tedious, don't it? To set the point clearance one must loosen the screw that retains the breaker spring. The rubbing block pivots on this screw when loosened. Place the feeler gauge with proper clearince in place with the rubbing block on the cam lobe then tighten the screw.

Design engineers could not make up their minds or give much thought to the poor souls faced with servicing these attempts at ignition. As Will Rogers spake: Life gets tedius, don't it? The stock condensers are nearly always defective. Always check for leakage. replace with modern automotive condenser and all will be well.If the condenser passes the electrical leakage test, which it probably won't, it should come in at about 0.18-.22MFD capacity.

A device for a 1971-73 Ford pinto with the 1599CC engine will fit with some modification. It is Niehoff FD-95, and BWD G590. To retrofit get a 6-32 hex head screw 3/8-1/2" long,poke it through the mounting tab then bend the mounting tab with the screw in place so the hex head faces the end of the condenser then use a nut and lockwasher to mount the device like the original. You may need to use a small rat tail file to enlarge the original hole slightly as it was for a #5 screw. Next connect the flag connector to the point stud where the stop switch lead connects and all condenser woes will go away.

Point clearance is important here as well as cam position that will determine engine timing as well as edge gap for optimum spark.

If the coils test good and all is well with the points and a new condenser is in place and still no spark there is a good chance that edge gap os out of spec. this is the interval determined by the space between the edge of the rotor and the stationary poleshoe as described above in the lower right. To get the biggest bang out of this design the edge gap with the breaker adjusted to spec is 5/64" or about .078" A #47 drill is a way to measure this.

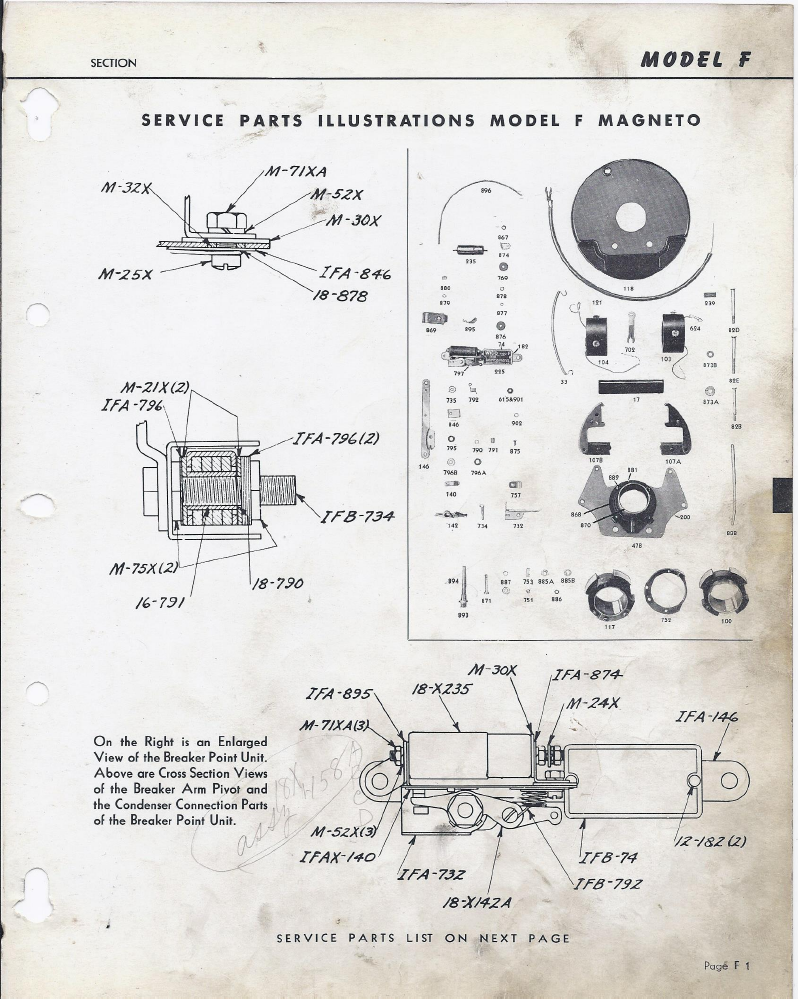

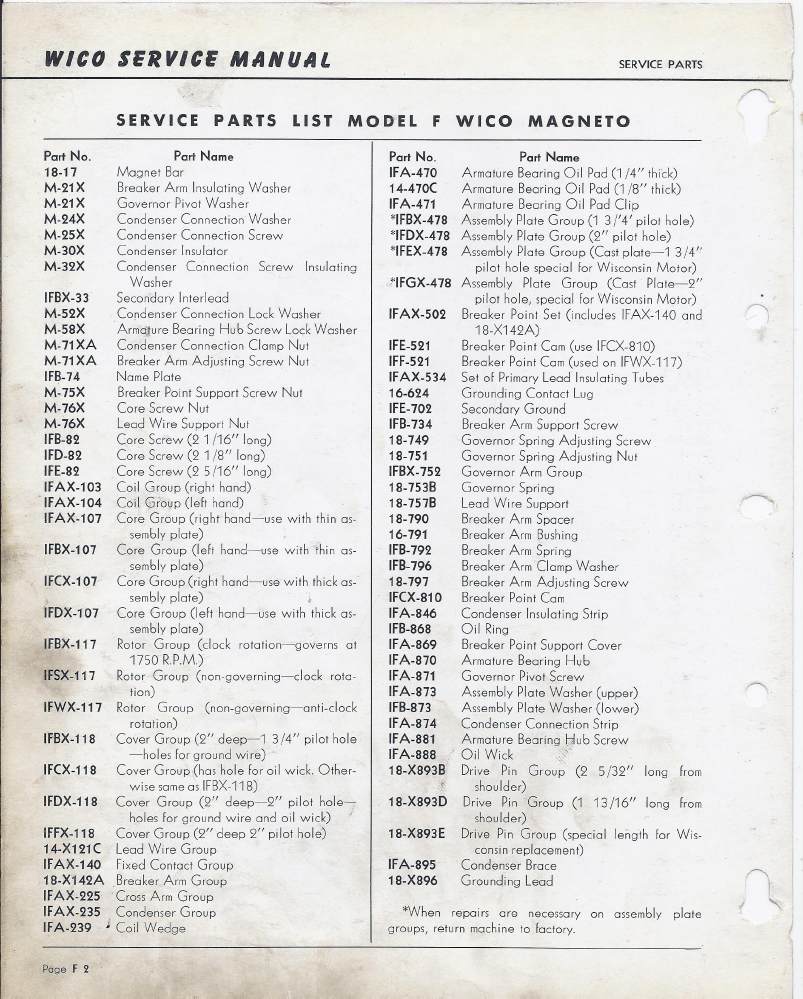

Here is the parts list for the model F.

More FG parts Information.